Hyspan Barco Ball Joints are available in standard and custom configurations 1/2″ through 30″ nominal pipe size. The following unpacked and packed configurations are available that will meet most requirements. Contact websales@Hyspan.com for additional sizes through 48″ or special design requirements.

Series 6600 Hyspan Barco Ball Joints

Information at a Glance

Series

6600 Hyspan Barco Ball Joints

![]()

Material

Steel

Size

1/2 -48 in. / 12-1200 mm

Pressure

≤100, 150 & 300 PSI / 3, 10 & 20 Bar

Motion

unlimited

Canadian Registration

![]()

This product is registered throughout Canada under

CRN 0D9278.59870YTNADD3

Other Products

Product Description

Technology & Advantages

The unique design of Hyspan Barco Ball Joints allows disassembly for inspection, seal replacement or other maintenance resulting in a product that lasts a lifetime.

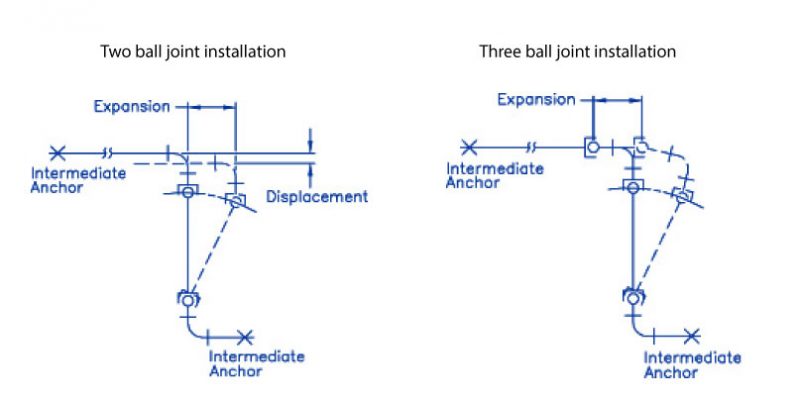

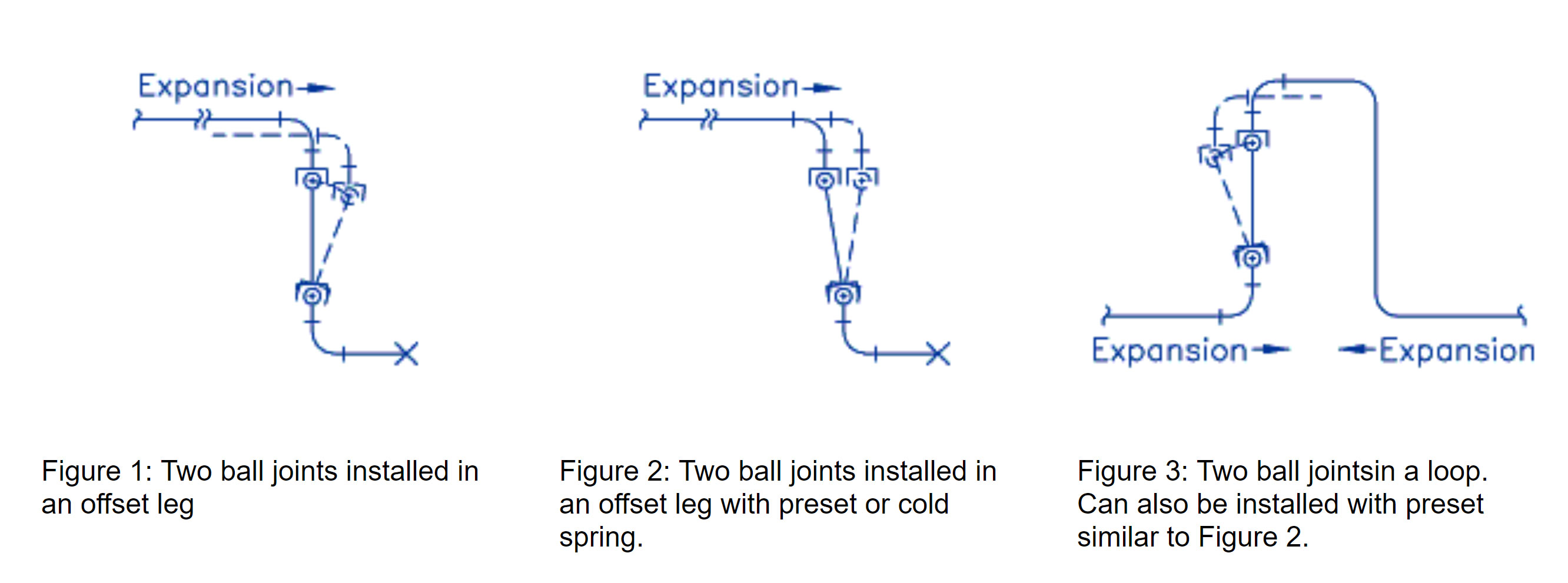

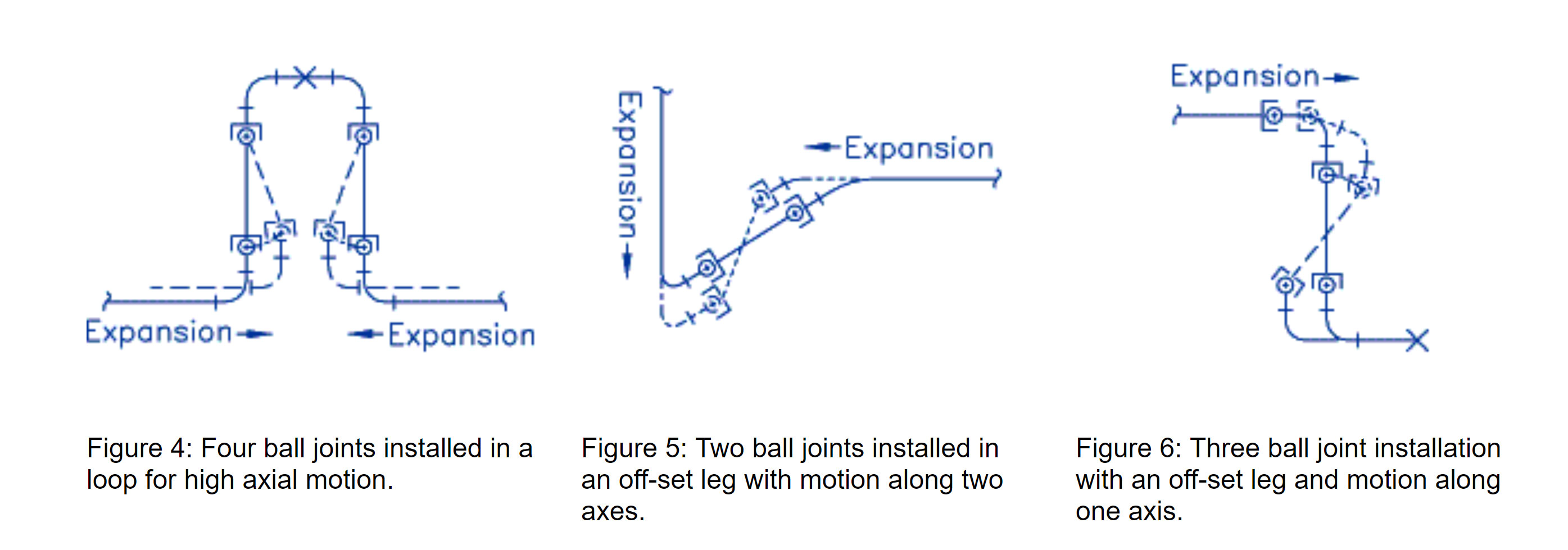

The Hyspan Barco Off-Set® Method utilizes two or three ball joints installed in a leg of the piping or a loop with the motion perpendicular to two ball joints installed in tandem. Two ball joints are satisfactory for most applications – a third joint may required for large movements.

Common Applications

Ball joints can be installed to absorb pipe movement in many applications ranging from thermal expansion or contraction of pipe, tank or building settlement, movement resulting from a seismic event, equipment movement such as solar panels and platens, and repetitive motion on bridges, oil platforms and ships. Regardless of the source of the motion, the ability of ball joints to absorb the motion relies on the Off-Set® Method.

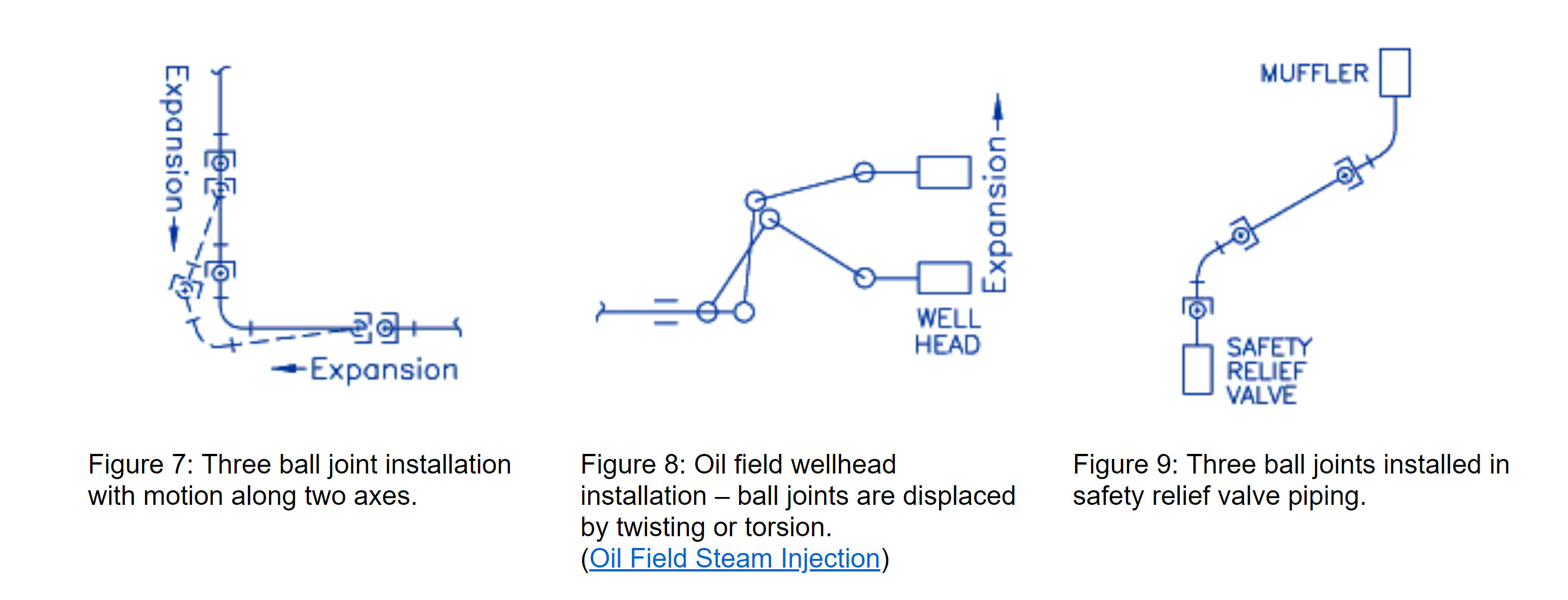

The following illustrations are typical installations of ball joints. They are primarily illustrated in one plane; however, ball joints are completely universal allowing motion in all planes including rotation around the centerline. No other method of absorbing pipe motion has this capability.

If you need additional assistance please contact the Hyspan Barco representative in your area or Hyspan at websales@hyspan.com .

Scissor linkage incorporating ball joints designed to absorb well head growth for steam injection wells in oil fields.

Hyspan Barco Type N Style II, ASME Classand OW1500 ball joints are commonly used to compensate for the thermal expansion of steam injection wells in oil fields. Depending on the well design, the growth can be as great as 1-2 meters (39-79 inches). The recommended ball joint installation for this application is a scissors arrangement shown in the adjacent illustration and photograph below. This arrangement deflects the ball joints in rotation.

- The orientation of the connections to the well head and supply pipe can be different than the illustration, but the center of rotation of all three ball joints must be in the same plane. For sizes 5″ NPS and larger, the scissor linkage must be guided and supported to maintain the in-plane alignment and to react the weight of the linkage.

- The supply pipe must be anchored (Main Anchor) as close as possible to the first ball joint. This anchor must be rigid and capable of reacting forces and moments in all planes with the exception (optional) that the supply pipe thermal expansion can be absorbed by allowing the pipe to travel horizontally through the anchor as illustrated. The purpose of the anchor is to maintain the position and configuration of the scissors linkage, react the forces and moments resulting from the internal resistance of the ball joints, and react the forces and moments within the supply piping.

- The supply pipe connection and well head connection can be at the same elevation or at different elevations as shown in the illustration. The well head “tree” provides an anchor that reacts the forces and moments resulting from the internal resistance of the scissors. The scissors connection to the “tree” should be as close as possible – avoid any long overhangs that provide a moment arm from the “tree” to the scissors.

- The included angle between the legs of the scissors should be approximately 90º at the installed condition, and should not exceed 130º when the well head is fully extended.

As a design aid, the Technical Assistance section includes design recommendations for the scissors linkage design, Leg Length Calculation for Ball Joint Scissor Arrangement. This calculation program provides a convenient method to develop the basic design of a well head connection following the recommendations described above. The complete scissor arrangement including the ball joints, pipe spools, elbows and end connections should fabricated in a shop environment with the end connections accurately located. The ball joints should be installed in the “as received” condition from the factory. They should not be rotated or deflected to assist with the fabrication of the scissors, and the Retainer should not be loosen to facilitate installation. A prefabricated scissors linkage with flanged connections is shown in the adjacent photograph. This completed assembly should be transported to the installation restrained to maintain the configuration. The “yellow” bar shown in the photograph provides this function.

The Hyspan Barco Ball Joints incorporate design features that are not available in comparable products.

- The design includes Inner and Outer Seals which rigidly position the ball, and the outer seal reacts the pressure thrust.

- The materials of the seals can be varied to be best suited to the design requirements.

- The cavity between the seals is injected with a mixture of graphite flakes and synthetic oil, Grafoil® Flexible Graphite.

- Additional graphite packing can be injected through the Injection Ports after the joints are in service without removing the joints. The procedure for injecting packing is described in the Installation and Maintenance Procedures for Type N Style II, ASME Class and OW1500 ball joints.

- All Hyspan Barco Ball Joints can be completely disassembled for inspection or maintenance. Sizes through 2″ NPS have threaded retainers and larger sizes have flanged retainers as shown in the illustrations.

- The removable retainers have the added benefit of allowing precision adjustment of the internal resistance (flex torque) of the ball joint.

Ball joint configurations for the heat transfer oil piping connecting the main header and crossover between mirrors for parabolic trough solar panels. Allows panels to rotate to track the sun.

Recommended ball joint installation for piping connections to tanks to compensate for displacement resulting from soil conditions.

Standard Catalog Ball Joint Designs

Hyspan Barco Ball Joints are available in standard and custom configurations 1/2″ through 30″ nominal pipe size. The following configurations are available that will meet most requirements. Contact websales@Hyspan.com for additional sizes through 48″ or special design requirements.

Ball Joint Types

Type N Style I

Type N Style I unpacked joints are available from 2 1/2″ through 30″ with Hyspan Barco proprietary Compound 11 composition seals or Compound 24 glass filled Teflon® seals. Type N Style I joints have a bolted retainer that permits seal adjustment or disassembly for maintenance. Type N Style I Hyspan Barco Ball Joints have evolved from the original ball joints that were developed by Barco in 1908 to distribute steam from locomotives to passenger cars for heating. The Type N Style I was developed in 1960. Since that time thousands of Style I joints have been installed in steam, hot water and chilled water distribution systems, used to absorb tank and building settling, used for seismic isolation and many other piping applications to compensate for expansion or to add flexibility to the system.

Type N Style II, III & III-V

Type N Style II, III & III-V ball joints are available from 2 ½” through 30”, designed with injected graphite flakes with synthetic oil carrier, Grafoil® Flexible Graphite, that provides lubrication in addition to sealing. Grafoil® combined with a variety of high strength bearing materials results in increased temperature and pressure ratings. Seal options include Hyspan Barco Compound 11 non-metallic composition material, Number 17 304 stainless steel, Number 21 ductile iron, Number 39 Alloy 625 high nickel stainless steel and Number 45 chrome-moly steel.

All Type N Style II, III & III-V ball joints permit repacking with Grafoil® after installation. Packing of Type N Style II ball joints is accomplished with the system pressure removed and the installation of a Recharge Cylinder. The Recharge Cylinders are a permanent part of Type N Style III & III-V thus permitting repacking with the system operating. The Style III-V has the added benefit of a Safety Valve to completely isolate the system pressure.

Type 14 Small Unpacked Ball Joints

Type 14 ball joints are available from ½” through 4” with Hyspan Barco proprietary Compound 11 composition seals or Compound 24 glass filled Teflon® seals. Type 14 unpacked ball joints have a threaded retainer that permits seal adjustment or disassembly for maintenance in a compact environment. The primary construction material is carbon steel with stainless steel options.

ASME Class Ball Joints Class 150 through 2500

ASME Class Hyspan Barco ball joints installed in flowline/riser connection of offshore platform.

Hyspan Barco ASME Class ball joints are designed to conform to the ratings established for ASME butt weld valves at 100ºF. Standard configurations are available 2″ through 30” NPS. Pressure class 150 through 2500.

The sealing system combines ductile iron or alloy steel with injected graphite flakes with synthetic oil carrier, Grafoil® Flexible Graphite. Grafoil® packing can be injected after installation if necessary.

ASME Class Ball Joints have been fire tested in accordance with API 6FA and approved by ABS Americas and Lloyd’s Register for shipboard applications.

OW1500 Style II and III-V Ball Joints

OW1500 Ball Joints are designed for 1500 psig and temperatures to 650ºF. They are commonly used to compensate for riser expansion on oil field wellheads, to compensate for solar panel rotation and other high-pressure applications.

OW1500 joints have ductile iron seals in combination with injected graphite flakes with synthetic oil carrier, Grafoil® Flexible Graphite. OW 1500 ball joints are designed to be repacked in service.

Type CSP Packed Solar Panel Connection Ball Joints

CSP Solar Ball Joints are available from 2” through 4” in Style II and III packed configurations. Developed from the OW1500 ball joints for the heat transfer oil piping connecting the main header and crossover between mirrors for parabolic trough solar panels. Allows panels to rotate to track the sun.

Note: Type Standard Series and Type 600 Series are discontinued, consult Hyspan for assistance.

Ordering Information

Hyspan products are available from Sales Representatives and Distributors, or they can be purchased direct from the factory. The minimum factory order for open account customers, COD shipments, or bank card sales is $100.00 (USD). All major credit or debit cards are accepted. The minimum order for new account applicants is $100.00. Our Confidential Credit Application can be downloaded and forwarded to Hyspan for processing. All orders are subject to the following Terms and Conditions, and the above warranty applies to all material. Please read these documents.

![]() Confidential Credit Application (13.9 KB), can be completed on line.

Confidential Credit Application (13.9 KB), can be completed on line.