Hyspan Barco Type N Style I Ball Joints

Information at a Glance

Series

6600 Hyspan Barco Ball Joints

Material

Steel

Size

1/2-48 in. / 12-1200 mm

Pressure

≤100, 150 & 300 PSI / 3, 10 & 20 Bar

Motion

unlimited

Canadian Registration

![]()

This product is registered throughout Canada under CRN 0D9278.59870YTNADD3

Other Products

Product Description

Type N Style I ball joints have been widely accepted since the design was introduced in 1960. They are commonly used in steam, hot water, chilled water, petroleum and chemical piping to absorb thermal expansion. Common applications are tank and building settlement, seismic isolation, bridge movement and wave motion compensation in addition to steam and hot water distribution systems.

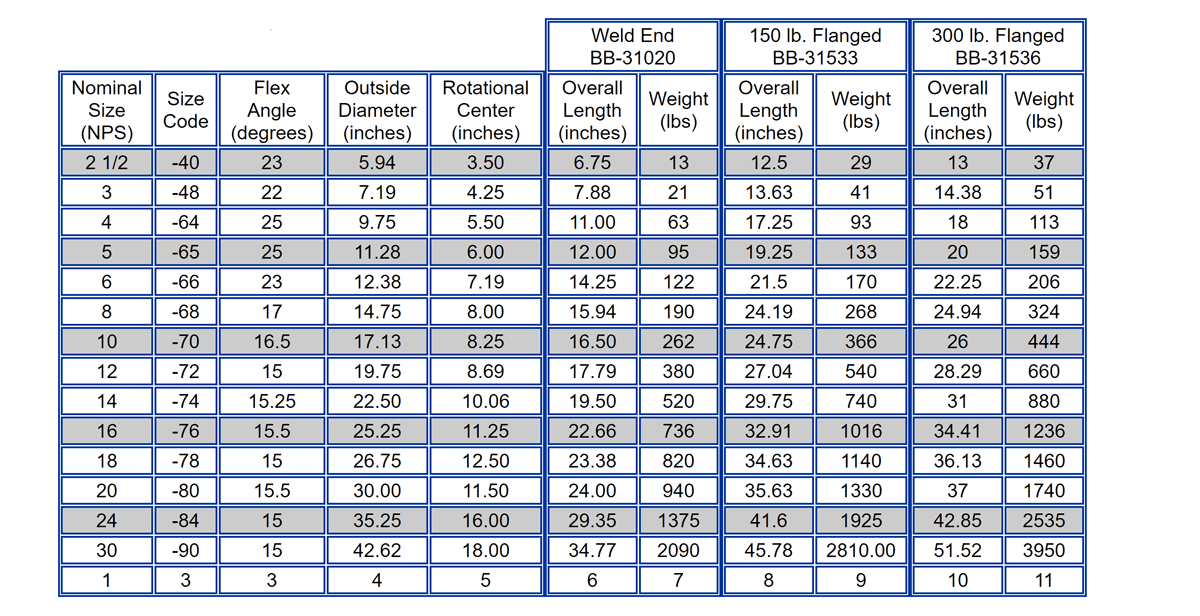

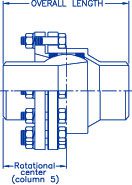

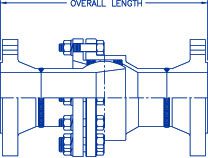

Standard models are available as weld end or flanged with optional seal materials. The total flex angle varies with size from 15º to 31º. Refer to Column 3 of the Dimensional Data below.

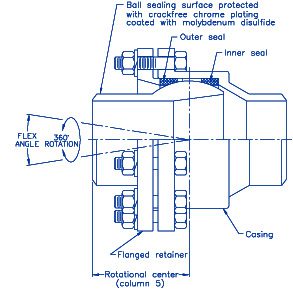

Standard materials are wrought steel for the ball, case and retainer. The ball sealing surface is protected with crack free chrome plating and coated with molybdenum disulfide.

Type N Style I Ball Joints

Flex torque is the moment (ft.-lbs.) at break-a-way to angularly displace a ball joint. Because the pressure thrust is reacted by the seals the flex torque is a function of pressure as illustrated by the adjacent charts for Number 11 composition seals. The values for Number 24 glass filled Teflon® seals are 15% less than the Number 11 seal values.

The values given are for steam service. For water or oil service the torque values are 45% less.

Seal Number 11

Compound 11 is a pressure molded proprietary seal compound recommended for general purpose applications for steam, hot water and oil systems. Compound 11 has the highest pressure/temperature ratings of the available seal materials.

Rated for service at temperatures from -50º F to +525º F.

Seal Number 24

Compound 24 is pressure molded proprietary compound of glass fiber and Teflon®. The addition of the glass fiber adds strength and stability to the seal. The compound is chemically inert and is recommended for applications involving corrosive fluids when a higher pressure rating is required.

Rated for service at temperatures from -325º F to +425º F.

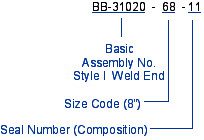

Ordering Instructions

To order or specify Hyspan Barco Ball Joints state the complete part number which includes; the basic Assembly Number selected from the illustrations, the Size Code from Column 2 of the Dimensional Data tabulation and the Seal Code based on the seal composition required.

To order or specify Hyspan Barco Ball Joints state the complete part number which includes; the basic Assembly Number selected from the illustrations, the Size Code from Column 2 of the Dimensional Data tabulation and the Seal Code based on the seal composition required.