25RECT Low Pressure Rectangle Bellows Expansion Joint

Information at a Glance

Series

2500 Low Pressure Round & Rectangular Bellows Expansion Joints

Material

Steel

Size

Rectangle Unlimited

Pressure

≤15 PSI / 1 Bar

Motion

3+ inches/75+ mm

Canadian Registration

![]()

This product is registered throughout Canada under

CRN 0D9278.59870YTNADD3

Other Products

Product Description

Series 2500 Rectangular Expansion Joints are all metal welded construction designed for very low positive and negative pressure applications such as flue ducts, exhaust systems, ventilation systems, fan connections and air supply systems. Since these ducts are sized to meet flow requirements and to mate with mechanical equipment, rectangular expansion joints are designed to match the duct and equipment sizes. They are manufactured with a variety of convolution profiles, corner designs and end attachments. Hyspan offers standard convolution profiles and corner designs as well as having the capability to manufacture custom designs.

Technology & Advantages

Series 2500 Rectangular Expansion Joints offer many benefits:

- Suitable for high temperature service without relying on internal insulation.

- All metal all welded construction provides a leak tight design.

- They can be designed to any size to meet specific duct or equipment sizes.

- Broad selection of materials for high temperature and corrosive service.

- Extended life – normal design life is 15 years

- Standard and custom bellows convolution profiles and corner designs are available.

Standard Hyspan Convolution Profiles

Hyspan standard LOCORR profile.

Hyspan LOCORR convolutions are recommended for ducting with dimensions ranging from 2.5 feet through 10 feet of length. The saw-tooth cross section provides high flexibility. They can be used with single or double miter, or camera fold corners.

Material: 0.040″ thick.

Axial Stroke: 0.375″ per convolution

Axial Spring Rate: 279 pounds per inch of stroke per foot of periphery

Hyspan standard HYCORR profile.

Hyspan HYCORR convolutions are recommended for ducting with dimensions greater than 10 feet. The saw- tooth cross section provides high flexibility. They can be used with single or double miter, or camera fold corners.

Material: 0.050″ thick.

Axial Stroke: 0.75″ per convolution

Axial Spring Rate: 59 pounds per inch of stroke per foot of periphery.

The most commonly used corner configurations are pictured below along with a description of their individual benefits. There are other corner designs such as rounded corners; however, there manufacturing limitations that restrict the depth of the convolutions and as a result have a lower flexibility.

Single Miter

This configuration is the most common design. The convolutions are joined by butt welds at each corner.

Double Miter

This configuration has an additional butt weld at each corner but has the benefit of the self draining configuration.

Camera Fold

The most flexible corner configuration. The convolutions are joined by edge welding

End Attachments

The most commonly used end attachments are illustrated below. Bolted angle flanges are the most common which have the benefit of stiffening the duct as well ease of installation and removal. As an alternative the flanges can be welded along the outer edges in place of bolting. Although they are not shown plate flanges are sometimes used.

Weld End

Angle Flange

Bolted or Welded at outer Edge

Landing Bar

Allows easy fit up

Design Data

Most rectangular expansion joints are used to absorb thermal expansion as axial travel or as connectors to isolate fans and other mechanical equipment. As a result most configurations are single unrestrained joints. There are no standard sizes since the ducts are individually fabricated and designed to accommodate the system design. Although Hyspan can fabricate other convolution profiles, the standard LOCORR and HYCORR profiles will accommodate most sizes, and they can be used with one of corner designs pictured. The end attachments are generally selected to conform with attachments used in the system or to mate with equipment. The most common end attachments are bolted flanges. The flanges have the added benefit of reinforcing the duct work.

Most rectangular expansion joints are used to absorb thermal expansion as axial travel or as connectors to isolate fans and other mechanical equipment. As a result most configurations are single unrestrained joints. There are no standard sizes since the ducts are individually fabricated and designed to accommodate the system design. Although Hyspan can fabricate other convolution profiles, the standard LOCORR and HYCORR profiles will accommodate most sizes, and they can be used with one of corner designs pictured. The end attachments are generally selected to conform with attachments used in the system or to mate with equipment. The most common end attachments are bolted flanges. The flanges have the added benefit of reinforcing the duct work.

Hyspan performs a design analysis on all designs in conformance with the method of analysis outlined in the Standards of the Expansion Joint Manufacturers Association, Inc.(EJMA). Rectangular expansion joints have stresses, and angular and lateral spring rates associated with the “long side” and “short side” sometimes referred to as the “easy way” and “hard way” and accordingly must be individually analyzed. In addition to these calculations Hyspan performs an analysis on the duct to determine if internal or external stiffeners are required to react the pressure forces.

Rectangular expansion joints are commonly furnished with flow liners to reduce pressure drop and prevent impingement of the flow on the bellows. The material used is frequently the same as the duct material. Most rectangular expansion joints are used in applications where the ducting is supported and anchored and the joint motion is axial; however, limit rods or tie rods are frequently incorporated into the design to prevent over travel.

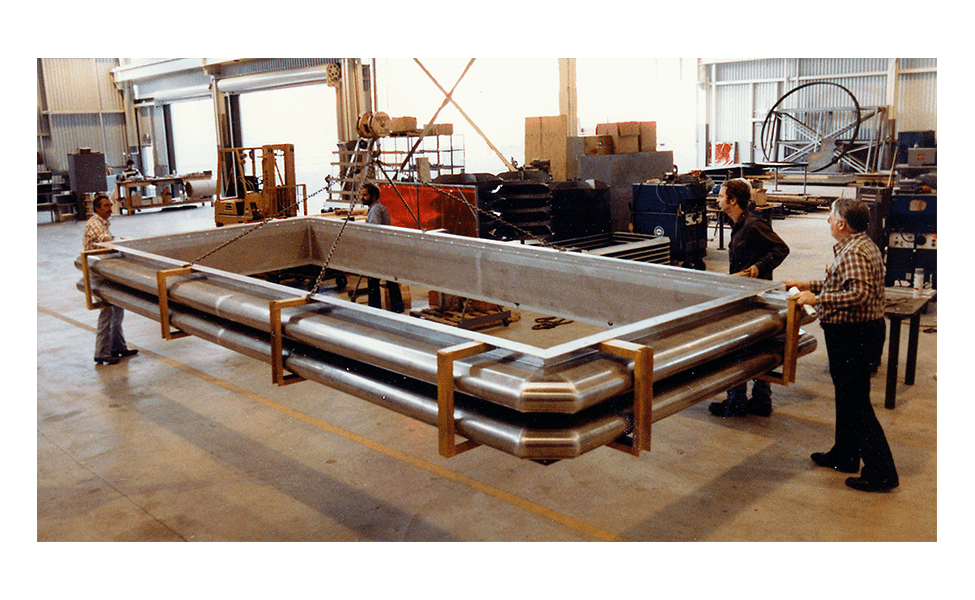

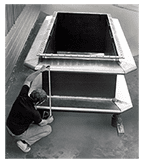

Single rectangular metal expansion joints have limited ability to absorb lateral offset or deflection. If lateral offset is a requirement a universal configuration is recommended or two single joints spaced apart. If the motion is limited to one plane, hinges or slotted hinges are frequently included. Slotted hinges have the benefit of stabilizing the expansion joint, limiting the axial travel and supporting the weight of adjacent ducting. The joint pictured is used in the exhaust stack of a ship. The rounded . ends are made from round expansion joints cut in half. This is the same technique is used to made round corners of rectangular expansion joints.

Single rectangular metal expansion joints have limited ability to absorb lateral offset or deflection. If lateral offset is a requirement a universal configuration is recommended or two single joints spaced apart. If the motion is limited to one plane, hinges or slotted hinges are frequently included. Slotted hinges have the benefit of stabilizing the expansion joint, limiting the axial travel and supporting the weight of adjacent ducting. The joint pictured is used in the exhaust stack of a ship. The rounded . ends are made from round expansion joints cut in half. This is the same technique is used to made round corners of rectangular expansion joints.

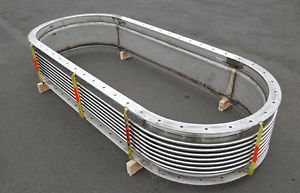

Although not common because of the added complexity, “race track” or “bath tub” joints are sometimes used. The joint pictured is used in the exhaust stack of a ship. The rounded ends are made from round expansion joints cut in half. This is the same technique is used to made round corners of rectangular expansion joints.

Ordering Information

Hyspan products are available from Sales Representatives and Distributors, or they can be purchased direct from the factory. The minimum factory order for open account customers, COD shipments, or bank card sales is $100.00 (USD). All major credit or debit cards are accepted. The minimum order for new account applicants is $100.00. Our Confidential Credit Application can be downloaded and forwarded to Hyspan for processing. All orders are subject to the following Terms and Conditions, and the above warranty applies to all material. Please read these documents.

Confidential Credit Application (13.9 KB), can be completed on line.